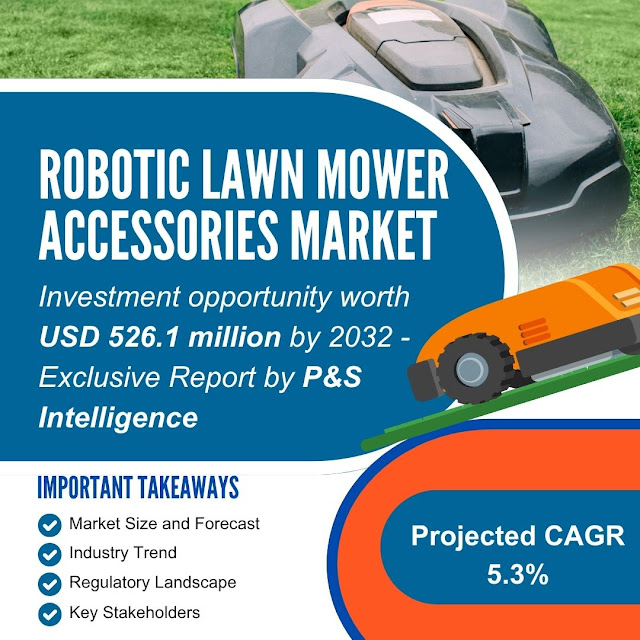

The robotic lawn mower accessories market is experiencing steady growth as smart home technology transforms traditional lawn care practices. Valued at USD 352.1 million in 2024, the market is projected to reach USD 526.1 million by 2032, advancing at a compound annual growth rate (CAGR) of 5.3% during the 2025-2032 period. This expansion reflects the growing adoption of automated lawn care solutions and the increasing sophistication of robotic mowing systems.

Smart Lawn Care Revolution

The rise of robotic lawn mowers has fundamentally changed

how homeowners approach yard maintenance, creating a thriving ecosystem of

accessories and complementary products. These automated systems offer

convenience, efficiency, and consistent results that traditional mowing methods

cannot match. As robotic mowers become more mainstream, consumers are investing

in accessories that enhance performance, extend functionality, and protect

their automated lawn care investments.

The accessories market encompasses a diverse range of

products including replacement parts, protective covers, charging stations,

boundary wire systems, security devices, and performance enhancement tools.

Weather protection accessories such as garage shelters and covers are

particularly popular, as they extend equipment lifespan and ensure consistent

operation across various climate conditions. Safety and security accessories,

including GPS tracking devices and theft deterrent systems, address growing concerns

about protecting valuable robotic equipment.

Market Drivers and Consumer Adoption

Several factors are driving robust growth in the robotic

lawn mower accessories market. The increasing adoption of smart home technology

has created consumer expectations for automated solutions that integrate

seamlessly with connected home ecosystems. Homeowners are embracing the

convenience of hands-free lawn maintenance, particularly as busy lifestyles

leave less time for traditional yard work.

Demographics play a crucial role in market expansion, with

aging populations in developed countries seeking solutions that reduce physical

demands of lawn care. Additionally, younger homeowners who grew up with

technology are more likely to adopt robotic lawn care solutions and invest in

accessories that optimize performance. The growing awareness of environmental

benefits associated with electric robotic mowers is also contributing to

increased adoption rates.

Property development trends are supporting market growth,

with new construction often incorporating larger lawns and complex landscaping

that benefit from automated maintenance solutions. Homeowners with premium

properties are willing to invest in high-quality accessories that ensure

optimal performance and protect their landscaping investments.

Technology Integration and Innovation

Modern robotic lawn mower accessories are becoming

increasingly sophisticated, incorporating advanced technologies that enhance

user experience and system performance. Smart charging stations with weather

monitoring capabilities, mobile app connectivity, and energy management

features represent the cutting edge of accessory innovation. These products

enable remote monitoring, scheduling optimization, and predictive maintenance

capabilities.

GPS tracking and security accessories have evolved to

include smartphone integration, real-time alerts, and sophisticated anti-theft

mechanisms. These accessories address one of the primary concerns potential

buyers have about robotic lawn mowers, making the technology more attractive to

security-conscious consumers.

Boundary wire systems and installation accessories have

become more user-friendly, with improved materials and simplified installation

processes that reduce setup complexity. Professional installation services and

DIY-friendly accessories are expanding market accessibility to consumers who

might otherwise be hesitant to adopt the technology.

Seasonal Demand and Maintenance Requirements

The robotic lawn mower accessories market exhibits distinct

seasonal patterns that influence sales cycles and inventory management. Spring

and early summer represent peak demand periods as homeowners prepare their

automated systems for the growing season. Replacement parts and performance

accessories experience highest demand during active mowing seasons, while

protective covers and storage solutions see increased sales as winter

approaches.

Maintenance accessories including blade replacements,

cleaning tools, and diagnostic equipment generate consistent demand throughout

the operating season. The recurring nature of these purchases creates stable

revenue streams for accessories manufacturers and retailers. Battery

replacement and charging system upgrades represent significant market segments

as early adopters of robotic mowing technology require equipment updates.

Distribution Channels and Market Access

The robotic lawn mower accessories market benefits from

diverse distribution channels that serve different consumer segments. Online

retail platforms have become increasingly important, offering comprehensive

product selections and detailed compatibility information that helps consumers

identify appropriate accessories for their specific mower models. E-commerce

platforms also enable direct-to-consumer sales from manufacturers, improving

margins while providing detailed product information.

Traditional retail channels including home improvement

stores, garden centers, and specialty lawn care retailers continue to play

important roles in market distribution. These channels provide hands-on product

evaluation opportunities and expert advice that many consumers value when

making accessory purchases. Professional landscaping services represent another

significant distribution channel, particularly for commercial-grade accessories

and installation services.

Regional Market Dynamics

North America and Europe represent the largest markets for

robotic lawn mower accessories, driven by high adoption rates of automated lawn

care technology and strong consumer spending on home improvement products.

Suburban landscapes with medium to large lawns create ideal conditions for

robotic mower adoption and subsequent accessory purchases.

The Asia-Pacific region is emerging as a significant growth market, with rapidly expanding middle-class populations and increasing focus on convenience technologies. Countries like Japan, South Korea, and Australia are experiencing particularly strong growth in robotic lawn care adoption, creating opportunities for accessories manufacturers.