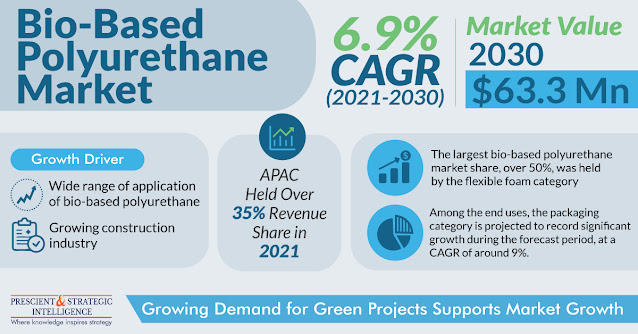

Since they have a smaller negative impact on the environment, are less expensive, are readily accessible, and degrade over time, bio-based polyurethane coatings have begun replacing petrochemical-based coatings in large quantities. The global bio-based polyurethane market accounted for $34.8 million in 2021, which is predicted to hit a $63.3 million value by 2030. This is owing to the various applications of this polymer, including footwear, biomedical, packaging, and transportation.

Furthermore, synthetic polyurethane compounds are toxic and non-biodegradable. They also use petrochemical-based raw resources, which are already running out, driving up the price of polyurethane manufacture. The bio-based version's excellent compressive strength, bending strength, tensile strength, and water absorption makes it superior to polyurethanes made from petroleum.

The flexible foam category maintained the biggest share in the bio-based polyurethane market, followed by rigid foam and coatings, sealants, and adhesives. Bio-based polyurethane foam that is flexible is strong, supporting, lightweight, and comfortable. A wide range of consumer and business products, including carpet underlay, mattresses, vehicle interiors, chairs, furniture, packaging, and specialty items, employ the material as cushioning. The fact that this material can be extremely stiff, soft, or even viscoelastic accounts for its popularity.

The packaging is expected to grow at a 9% CAGR in the bio-based polyurethane market. One-component polyurethane adhesives are widely used in printed films, snack food bags, and shopping bags. In addition, polyvinyl chloride is attached to aluminum sheets for medical applications using a customized two-component polyurethane adhesive. Furthermore, due to its low viscosity and low application temperature, hot-melt polyurethane is ideally suited for wrapping applications.

Buildings that are environmentally friendly and cost-effective to operate are gaining popularity. The World Green Building Council, central organizations like the Ministry of Skill Development & Entrepreneurship, the SIDBI, and the GSA in the U.S., as well as state governments and municipal bodies internationally, have all recognized and rewarded green buildings.

Due to their high strength, bio-based polyurethanes are utilized in a variety of applications, including roofing, window and door profiles, pipes and gutters, glazing, cement, insulation, hardwood flooring, sealants & adhesives, heavy-duty rubber flooring, and parquet gluing. Due to their capacity to have high green strength, bond wet/frozen timber, and shear strength, they are also commonly used for ceramic tiles, bathtub surrounds, concrete, and mirrors.

No comments:

Post a Comment