Nitrile rubber, commonly known as nitrile-butadiene rubber (NBR), is a synthetic rubber that resists oil and is made from a copolymer of butadiene and acrylonitrile. Its primary uses are gasoline hoses, rollers, gaskets, and other items where oil resistance is necessary.

When great oil resistance is needed, such as gaskets, automobile seals, or other components that come into contact with hot oils, nitrile rubber is typically employed. Other apparent uses include hoses for rollers and oil products for spreading ink in printing. NBR is also used in the textile industry to enhance the waterproofing and finish of woven and nonwoven materials.

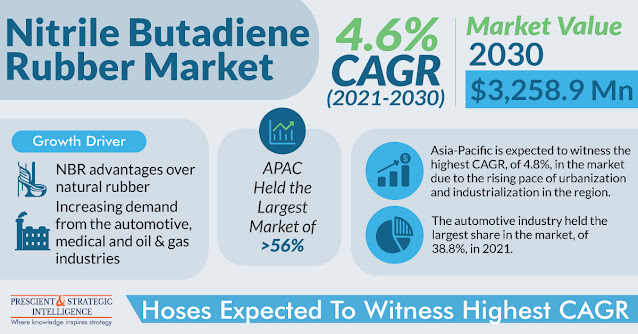

The nitrile butadiene rubber market will hit $3,258.9 million value by 2030. This is attributed to the material's rising demand from the oil & gas, automotive, and medical sectors, where components must have excellent thermal stability and oil resistance.

What Is the Purpose of Nitrile Rubber?

When oil resistance, performance in high temperatures, and personal safety are required, nitrile rubber is frequently used. It is frequently used in the automobile sector for parts, including engine hoses, gaskets, oil seals, and O-rings, because of its resistance to hot oil.

Because of its wide operating temperature range, nitrile is used in aircraft applications such as bladders and self-sealing fuel tanks. Additionally, it is utilized in textiles to enhance the finish and waterproof cloth. Due to its durability and hypoallergenic properties, nitrile safety gloves may be its most well-known use.

Hoses Are Expected to Experience Highest CAGR

The CAGR for hoses will be the highest in the upcoming years. Since the qualities of nitrile buna-N rubber may be changed by varying the acrylonitrile proportion, manufacturers can produce distinctive goods. It can increase its elasticity, heat, abrasion, and break resistance.

As an illustration, some rubbers that cure fast preserve the polymer's oil resistance while enabling possible molding applications, such as minimizing mold fouling. The materials produced can be utilized for uses involving food and drinking water and for molded rubber components such as hoses, seals, and membranes.

Fastest Growing Region

Due to rising hospital admissions, the demand for personalized medication, the prevalence of chronic diseases, and advancements in medical technology, the APAC nitrile butadiene rubber market is expanding.

Most importantly, the region's need for NBR latex has surged due to the COVID-19 pandemic. NBR latex is replacing natural rubber latex because it operates better under difficult conditions, especially in the glove sector.